What are Industrial Hygiene Services?

What are Industrial Hygiene Services?

We leverage our expertise in OSHA, ACGIH, NIOSH, ANSI, and other industry standards or guidelines to evaluate Industrial Hygiene procedures, policies, programs and potential exposures. We developing relevant recommendations that protect your employees’ health while reducing redundancies, speeding projects, and reducing costs.

What are the key benefits?

CanAm Environmental Safety, Inc. develops long-term strategies to assure continuous compliance, improve processes, and support of best management practices. With industry experience from military contracts to large manufacturing to small businesses to corporate giants, we can quickly pinpoint and deliver practical, client-specific solutions for a healthier workplace. By developing relationships with our clients that are based on trust, responsibility, technical expertise, and efficiency, CanAm provides effective solutions to emerging, immediate and long-term Industrial Hygiene issues.

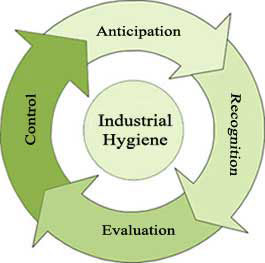

Our Approach.....

Every client’s needs are unique. Our approach recognizes that fact and provides for client-specific implementation of:

Evaluation of Hazards

Industrial hygiene hazards are identified and assessed to determine the best approach to protecting the worker by controlling the hazards and meeting the applicable regulatory requirements. Based on the information developed, a client-specific strategy is devised and put into motion from our menu of services.

Implementation

CanAm's expertise in regulatory requirements and professional guidelines is applied to implement Industrial Hygiene exposures assessment strategies, programs, procedures and policies that achieve a safe and healthy workplace with minimal cost and time investments. Long-term strategies are put into place to ensure compliance and a safe work environment into the future.

Reporting

Reporting is customized based on the strategies implemented, and client characteristics, such as number of facilities, duration of project, and long-term goals. Written reports compare the assessment results with regulatory requirements and professional guidelines to provide a frame of reference, and in cases of large projects, reports can be provided in a searchable database to allow viewing of exposure results by facility type, location, job classifications, etc.

FAQ - Frequently Asked Questions

What is a CIH?

CIH stands for Certified Industrial Hygienist. It is a mark of professionalism given by the American Board of Industrial Hygiene. It is only for those individuals meeting extensive professional and educational requirements. All CIHs are bound by the Code of Ethics.

What are common industrial hygiene problems?

Common industrial hygiene problems include: chemical hazards like mists, vapors from toxic solvents, dusts from asbestos, and fumes from welding.

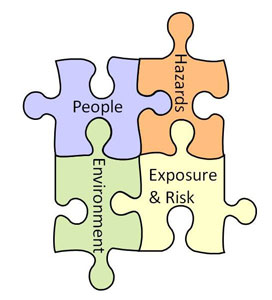

Exposure Risk Assessments

Loss work days are one of the highest preventable costs that companies face in recent years. Through the use of exposure risk assessments, loss time incidences can be reduced. The risk assessment begins with a review of loss time incidences throughout a company, followed by an analysis of those operations with the highest loss time incidence rates. These operations can then be examined to determine where exposure risks can be reduced through either changing work practices, controlling hazard exposures, or through designing a healthier operation process.

Exposure to welding fumes during MIG, TIG, laser and arc welding are assessed using NIOSH validated methods.

Baseline Exposure Monitoring

Most industrial facilities have no air monitoring data for operations at their facility, which most regulatory agencies do not like to observe. Therefore, conducting baseline exposure monitoring on all operations that may have potential exposure hazards is a proactive measure that employers can undertake. The results of the baseline exposure monitoring will provide data to the employer indicating potential exposures with specific operations as well as possibly preventing monetary fines from regulatory agencies. The data can be used to determine if some hazard control measures may be necessary and which operations and/or employees may require periodic exposure monitoring whereby products, materials, and processes are changed.

CanAm Exposure Monitoring Services

For all of your company exposure monitoring needs call CanAm Environmental Safety, Inc. today! (585) 261-3205